BOE Website

Data display board

Data display board

Production management conferences at all levels

production data smart display board

Production line abnormality alarm

Production line abnormality alarm

Proactive monitoring of production abnormalities

threshold alarm e-mail

Online indicator assessment

Online indicator assessment

Factory operation management indicators

other operation indicators

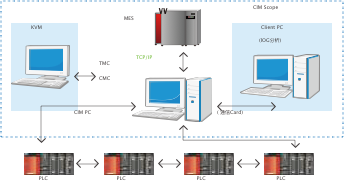

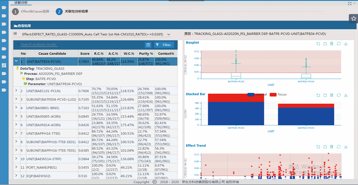

Smart monitoring and analysis

Smart monitoring and analysis

Quick root cause targeting by smart monitoring and analysis

establishment of industrial smart analysis knowledge bases

- About BOE

- Exhibition Events

- Innovation Platform

- Investor Relations

- Join Us

Copyright © 2020 BOE Technology Group Co., Ltd. All rights reserved

Beijing public network security 11010502026582

Beijing public network security 11010502026582

Beijing public network security 11010502026582

Beijing public network security 11010502026582